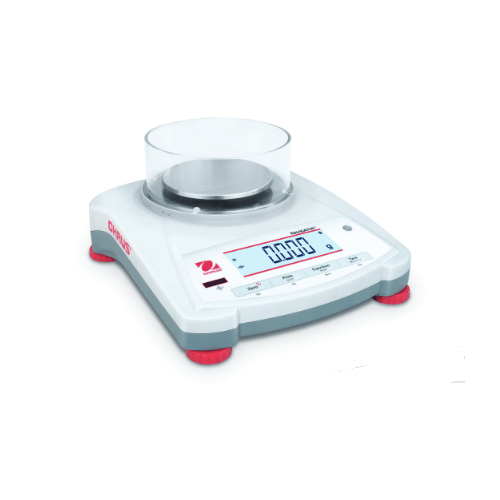

EX224/AD 220g X 0.1mg - 320g X 0.1mg - Explorer Analytical Balance

1 in stock! Order now.

EX224/AD features:

- The EX224/AD has a measuring capacity of 220 - 320 grams with a resolution of 0.1 milligrams for precise measurements.

- Has a 5.7 inch (145 mm) Full-colour VGA graphic touchscreen display with user-controlled brightness.

- Modular design, metal base, ABS top housing, stainless steel pan illuminated up-front level indicator, integral weigh below hook, security bracket, calibration lock, four touchless sensors, and full housing in-use cover.

- Design features include selectable environmental filters, auto tare, user selectable span calibration points, software lockout and reset menu, user selectable communication settings and data print options, user definable project and user IDs, auto standby, and up to 14.

- Pan size of 90 mm.

- Integrated with RS232 and USB features with GLP/GMP data output with real time clock.

- Additional RS232/ethernet accessories for additional data upload options.

- All Explorer balance has A large colour touchscreen gives access to the advanced application modes and icon-driven application software features such as user manager, library, and minimum weight indication.

- Explorer features fast stabilisation times, optimised linearity and repeatability specifications, enhanced vibration filtering and the choice of traditional calibration or AutoCal models.

- Explorer's sturdy modular design includes metal housing and a display that can be separated from the weighing base and tower or wall-mounted for easy viewing in any workspace.

- Four years warranty

Weighing Functions:

- Weighing - Determine the weight of items in the selected unit of measure. Minimum Weight feature is also available|

- Percent Weighing - Measure the weight of a sample displayed as a percentage of a pre-established Reference Weight.

- Dynamic Weighing - Weigh an unstable load. Balance takes an average of weights over a time period.

- Totalization - Measure cumulative weight of multiple items. Cumulative total may exceed Balance capacity.

- Differential Weighing - Store sample weights and calculate the difference between initial weights and final weights.

- Peak Hold - Capture and store highest weight in a series. Both stable and unstable weights are captured.

- Parts Counting - Count samples of uniform weight. Choose Standard Counting, Check Counting, or Fill Counting.

- Pipette Adjustment - Check pipette values by weight analysis, with built-in water density table.

- Check Weighing - Compare the weight of a sample against target limits. Choose from Standard, Nominal-weight, or Nominal-Percent.

- Filling - Fill a container to a target weight. Progress bar displays filling status.

- Formulation - For compounding and recipe making. The number of components can be from two to 99.

- Density Determination - Determine density of solids more dense than water, solids less dense than water, liquids, or porous material.

- Ingredient Costing - Determine cost of formula or recipe based on known cost/quantity of components or ingredients.

- SQC - Monitor and/or control processes to eliminate under and over filling.